Product Description

High-strength stainless steel hose clamp (commonly known as a T-bolt clamp or single-bolt hose clamp) is primarily used for pipe connections in high-pressure environments.

Material Specifications: The clamp is marked "W4," indicating it is made entirely of 201 or 304 stainless steel, offering extremely high corrosion resistance.

Application Range: Such as: The "40-43" marking on the steel strip indicates its adjustable tightening diameter range of 40 mm to 43 mm.

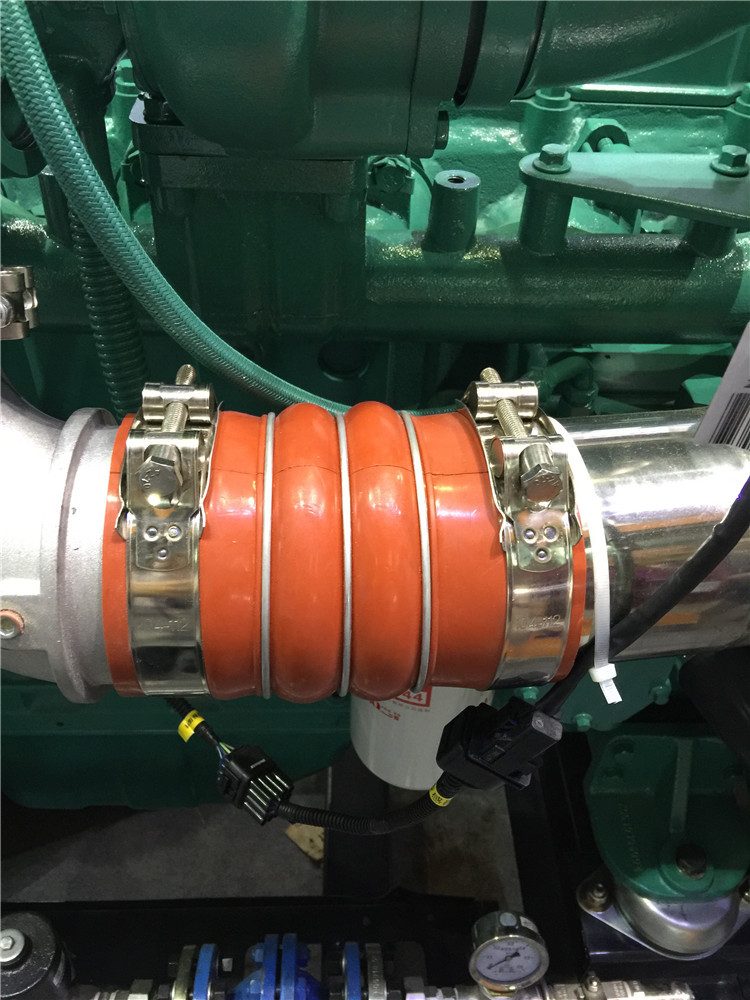

Core Applications: Designed for heavy-duty sealing applications such as turbocharger hoses, high-pressure engine coolant hoses, and industrial exhaust pipes.

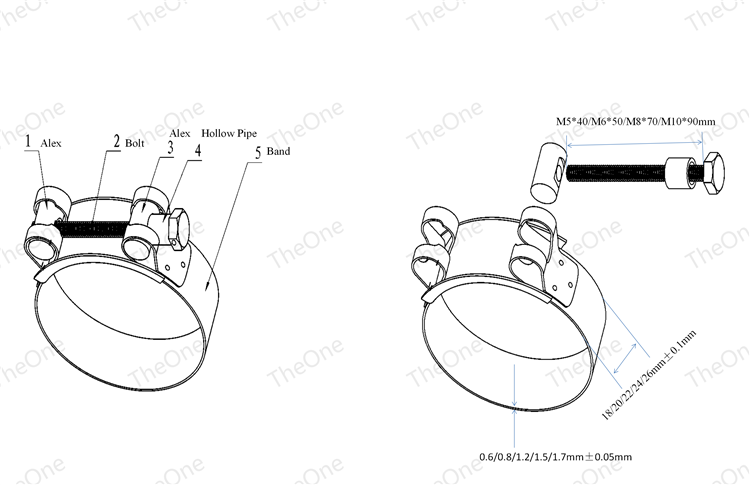

Design Features: Utilizing a single-bolt design, it provides more even pressure and greater torque compared to standard hose clamps, preventing hose detachment or leakage.

|

NO. |

Parameters | Details |

|

1. |

Bandwidth*thickness | 1) zinc plated :18*0.6/20*0.8/22*1.2/2*1.5/26*1.7mm |

| 2) stainless steel:18*0.6/20*0.6/2*0.8/24*0.8/26*1.0mm | ||

|

2. |

Size | 17-19mm to all |

|

3. |

Screw | M5/M6/M8/M10 |

|

4. |

Break Torque | 5N.m-35N.m |

|

5 |

OEM/ODM | OEM /ODM is welcome |

Product Video

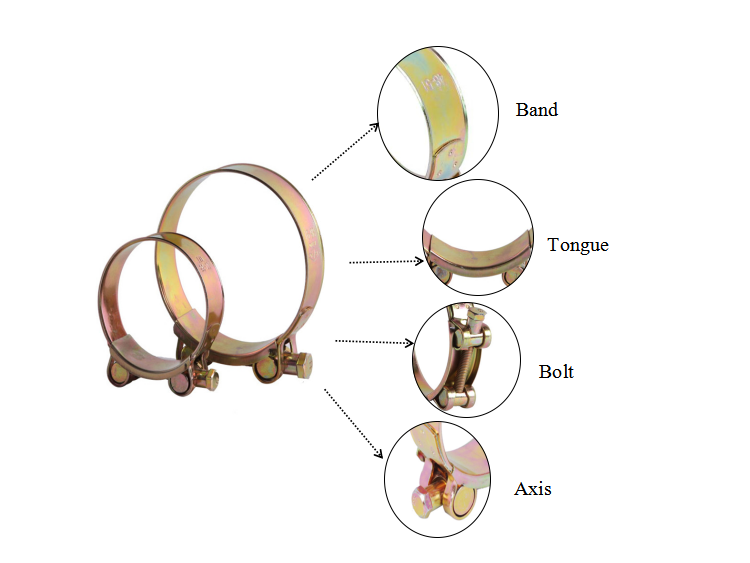

Product Components

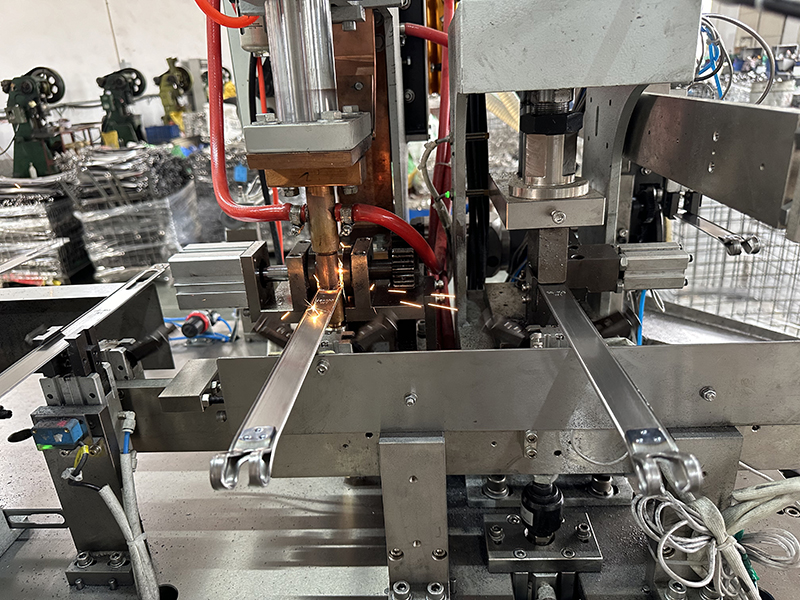

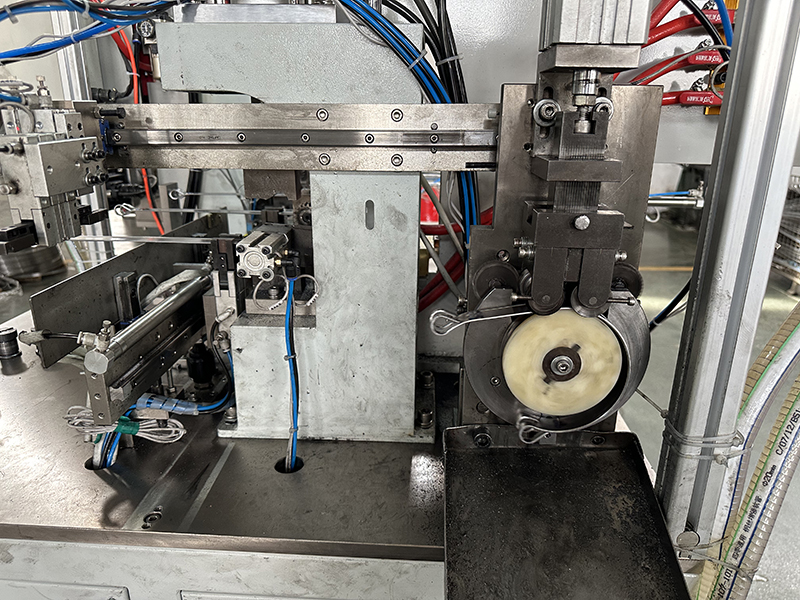

Production Process

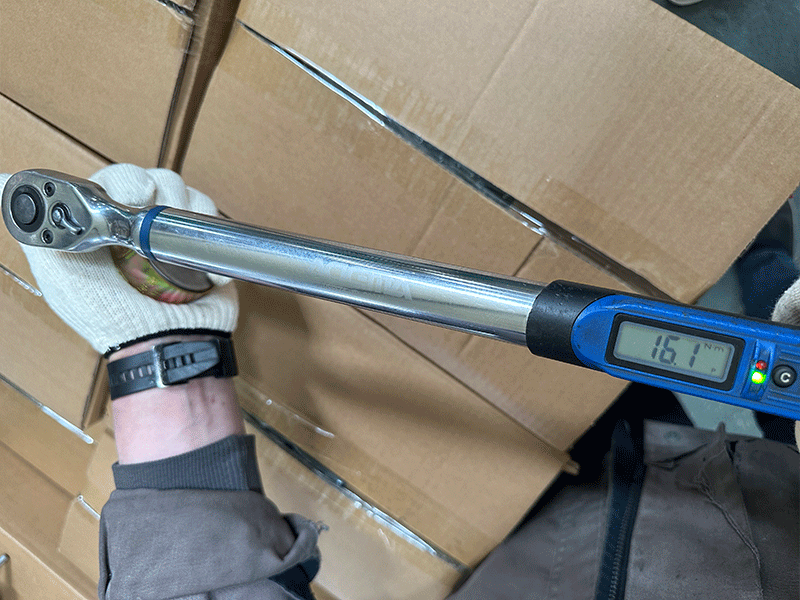

Load Torque Testing

Production Application

The bolt clamp (specifically a heavy-duty T-bolt or robust clamp) is used to provide a high-pressure, uniform seal for securing various types of hoses and pipes in demanding industrial and automotive environments.

Product Advantage

- High-Pressure Applications: They are specifically designed for applications where standard worm-gear clamps might fail, such as turbo pressure hoses and high-pressure engine cooling systems.

- Automotive and Motorbike Use: These clamps are frequently used to secure motorcycle exhaust pipes, mufflers, and silencers due to their robust construction and resistance to vibration.

- Industrial Piping: They are utilized in hydraulic systems and for securing thick-walled or reinforced hoses that require significant torque to create a proper seal.

- Material Durability: Typically made of stainless steel (such as grade 304), they offer high corrosion resistance and a long service life in harsh conditions.

- Installation: The clamp is used by sliding it over the pipe or hose and tightening the bolt (as seen in the image) until the two halves are pulled together to create a heavy-duty, leak-proof seal.

Packing Process

Box packaging: We provide white boxes, black boxes, kraft paper boxes, color boxes and plastic boxes, can be designed and printed according to customer requirements.

Transparent plastic bags are our regular packaging, we have self-sealing plastic bags and ironing bags, can be provided according to customer needs, of course, we can also provide printed plastic bags, customized according to customer needs.

Generally speaking, the outer packaging are conventional export kraft cartons, we can also provide printed cartons according to customer requirements: white, black or color printing can be. In addition to sealing the box with tape, we will pack the outer box, or set woven bags, and finally beat the pallet, wooden pallet or iron pallet can be provided.

Certificates

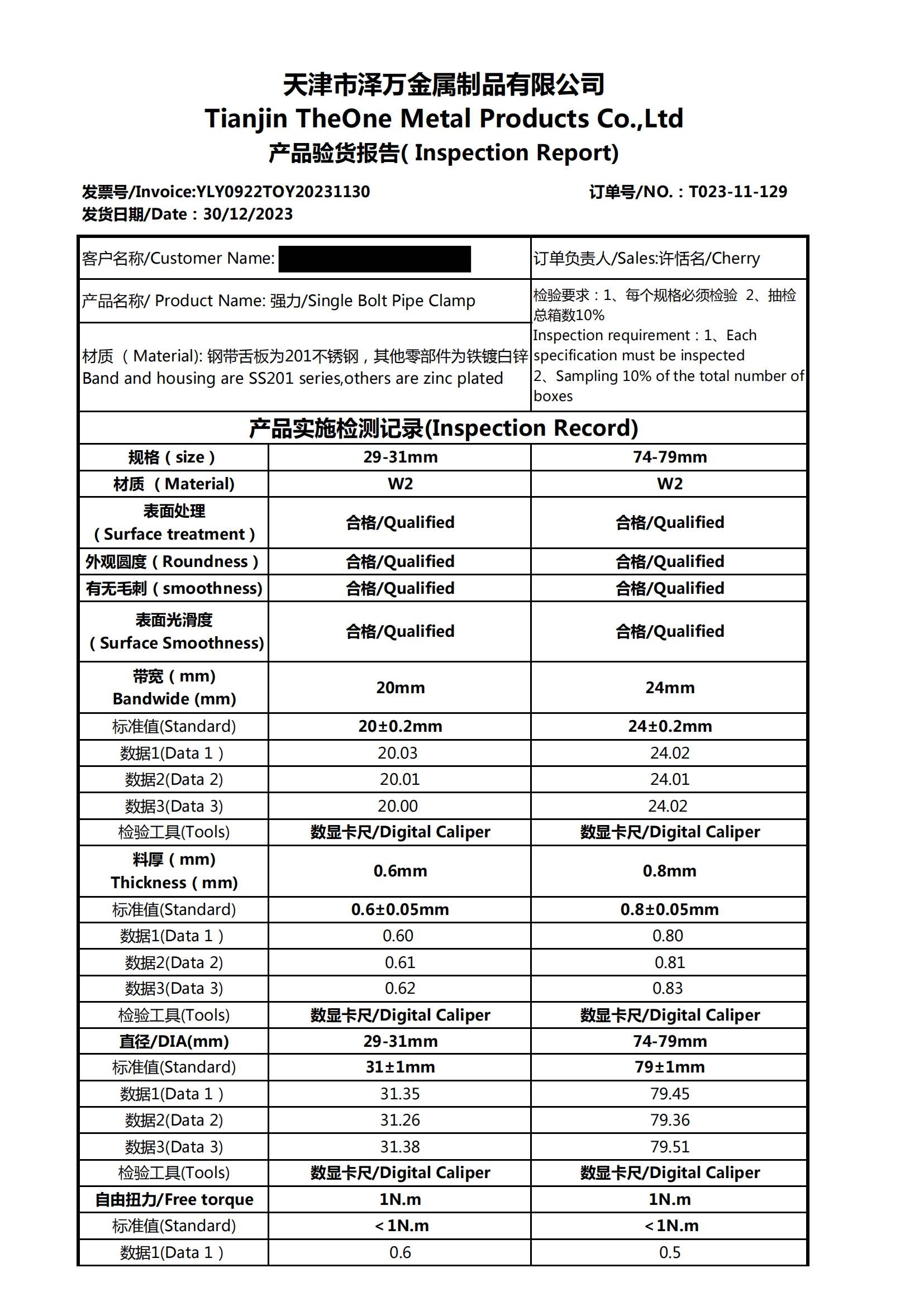

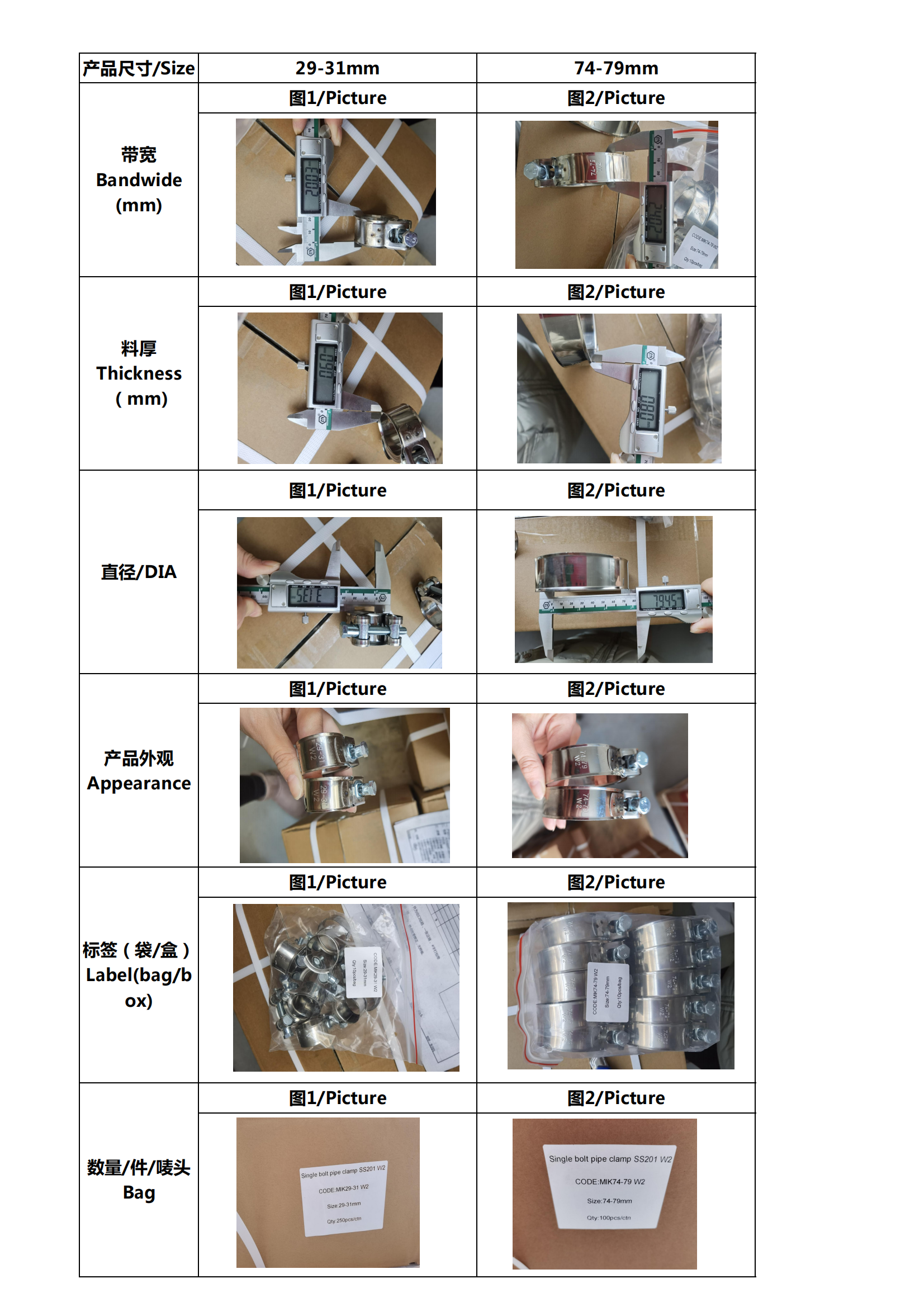

Product Inspection Report

Our Factory

Exhibition

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory welcome your visit at anytime

Q2: What’s the MOQ?

A: 500 or 1000 pcs /size,small order is welcomed

Q3: How long is your delivery time?

A: Generally it is 2-3 days if goods are in stock. Or it is 25-35 days if the goods are on producing, it is according to your

quantity

Q4: Do you provide samples? Is it free or extra?

A: Yes, we could offer the samples for free only you afford is freight cost

Q5: What is your terms of payment?

A: L/C, T/T ,western union and so on

Q6: Can you put our company’s logo on the band of the hose clamps?

A: Yes, we can put your logo if you can provides us with copyright and letter of authority, OEM order is welcomed.

|

Clamp Range |

Bandwidth |

Thickness |

TO PART NO. |

||||

|

Min(mm) |

Max(mm) |

(mm) |

(mm) |

W1 |

W2 |

W4 |

W5 |

|

17 |

19 |

18 |

0.6/0.6 |

TORG19 |

TORS19 |

TORSS19 |

TORSSV19 |

|

20 |

22 |

18 |

0.6/0.6 |

TORG22 |

TORS22 |

TORSS22 |

TORSSV22 |

|

23 |

25 |

18 |

0.6/0.6 |

TORG25 |

TORS25 |

TORSS25 |

TORSSV25 |

|

26 |

28 |

18 |

0.6/0.6 |

TORG28 |

TORS28 |

TORSS28 |

TORSSV28 |

|

29 |

31 |

20 |

0.6/0.8 |

TORG31 |

TORS31 |

TORSS31 |

TORSSV31 |

|

32 |

35 |

20 |

0.6/0.8 |

TORG35 |

TORS35 |

TORSS35 |

TORSSV35 |

|

36 |

39 |

20 |

0.6/0.8 |

TORG39 |

TORS39 |

TORSS39 |

TORSSV39 |

|

40 |

43 |

20 |

0.6/0.8 |

TORG43 |

TORS43 |

TORSS43 |

TORSSV43 |

|

44 |

47 |

22 |

0.8/1.2 |

TORG47 |

TORS47 |

TORSS47 |

TORSSV47 |

|

48 |

51 |

22 |

0.8/1.2 |

TORG51 |

TORS51 |

TORSS51 |

TORSSV51 |

|

52 |

55 |

22 |

0.8/1.2 |

TORG55 |

TORS55 |

TORSS55 |

TORSSV55 |

|

56 |

59 |

22 |

0.8/1.2 |

TORG59 |

TORS59 |

TORSS59 |

TORSSV59 |

|

60 |

63 |

22 |

0.8/1.2 |

TORG63 |

TORS63 |

TORSS63 |

TORSSV63 |

|

64 |

67 |

22 |

0.8/1.2 |

TORG67 |

TORS67 |

TORSS67 |

TORSSV67 |

|

68 |

73 |

24 |

0.8/1.5 |

TORG73 |

TORS73 |

TORSS73 |

TORSSV73 |

|

74 |

79 |

24 |

0.8/1.5 |

TORG79 |

TORS79 |

TORSS79 |

TORSS79 |

|

80 |

85 |

24 |

0.8/1.5 |

TORG85 |

TORS85 |

TORSS85 |

TORSSV85 |

|

86 |

91 |

24 |

0.8/1.5 |

TORG91 |

TORS91 |

TORSS91 |

TORSSV91 |

|

92 |

97 |

24 |

0.8/1.5 |

TORG97 |

TORS97 |

TORSS97 |

TORSSV97 |

|

98 |

103 |

24 |

0.8/1.5 |

TORG103 |

TORS103 |

TORSS103 |

TORSSV103 |

|

104 |

112 |

24 |

0.8/1.5 |

TORG112 |

TORS112 |

TORSS112 |

TORSSV112 |

|

113 |

121 |

24 |

0.8/1.5 |

TORG121 |

TORS121 |

TORSS121 |

TORSSV121 |

|

122 |

130 |

24 |

0.8/1.5 |

TORG130 |

TORS130 |

TORSS130 |

TORSSV130 |

|

131 |

139 |

26 |

1.0/1.7 |

TORG139 |

TORS139 |

TORSS139 |

TORSSV139 |

|

140 |

148 |

26 |

1.0/1.7 |

TORG148 |

TORS148 |

TORSS148 |

TORSSV148 |

|

149 |

161 |

26 |

1.0/1.7 |

TORG161 |

TORS161 |

TORSS161 |

TORSSV161 |

|

162 |

174 |

26 |

1.0/1.7 |

TORG174 |

TORS174 |

TORSS174 |

TORSSV174 |

|

175 |

187 |

26 |

1.0/1.7 |

TORG187 |

TORS187 |

TORSS187 |

TORSSV187 |

|

188 |

200 |

26 |

1.0/1.7 |

TORG200 |

TORS200 |

TORSS200 |

TORSSV200 |

|

201 |

213 |

26 |

1.0/1.7 |

TORG213 |

TORS213 |

TORSS213 |

TORSSV213 |

|

214 |

226 |

26 |

1.0/1.7 |

TORG226 |

TORS226 |

TORSS226 |

TORSSV226 |

|

227 |

239 |

26 |

1.0/1.7 |

TORG239 |

TORS239 |

TORSS239 |

TORSSV239 |

|

240 |

252 |

26 |

1.0/1.7 |

TORG252 |

TORS252 |

TORSS252 |

TORSSV252 |