Hose clamps are primarily used to secure and seal hoses and tubing to fittings and pipes. Worm drive hose clamps are very popular because they are adjustable, easy to use and require no special tools—a screwdriver, nut driver or socket wrench is all that is needed to install and remove. A captive screw/worm gear mates with slots in the band to adjust the diameter of the clamp over a specified range. The band can be fully released (opened) so hose clamps can be installed on hoses and tubing already in place. They are also used for a variety of non-hose applications, like attaching or connecting one object to another. Hose clamps are reusable and are also known as:

worm drive clamps, worm gear clamps, worm screw clamps.

Hose clamp size refers to their clamping diameter range, which is listed as a minimum and maximum useable diameter, in inches; some clamps are also specified by their SAE (Society of Automotive Engineers) size. To determine the size needed, install the hose (or tubing) on the fitting or pipe (which expands the hose), measure the outside diameter of the hose, then select a clamp that accommodates that diameter in about the middle of its range. If the installed outside circumference of the hose is known, divide it by 3.14 (pi) to convert circumference to diameter.

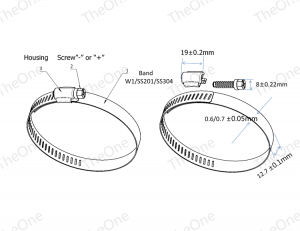

Standard series hose clamps are the most common and are found in vehicle and industrial applications. Minimum clamp diameter is 3/8″ and the typical maximum is about 8 7/16″. They have 1/2″ wide bands and 5/16″ slotted hex head screws. These clamps meet or exceed SAE torque specifications.

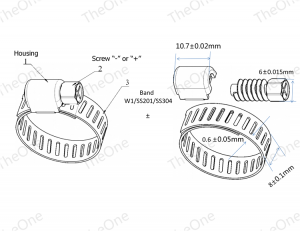

Miniature series hose clamps are used with small diameter hoses and tubing such as air, fluid and fuel lines. The minimum diameter is 7/32″ and the maximum is about 1 3/4″. The bands are 5/16″ wide and the screw is a 1/4″ slotted hex head. Their small size permits installation in confined places.

Although hose clamps can be connected end-to-end to create custom or large sizes, consider using Create-A-Clamp instead to make clamps up to 16 ft in diameter. Kits include a 50 ft roll of 1/2″ wide banding that is easily cut to length, 20 fasteners (slotted band ends and housings with captive screw/worm gear), and 10 splices for combining shorter lengths of banding. All components are stainless steel and 5/16″ slotted hex head screws are standard. Unlike other banding/strapping systems, no special tools are required other than tin snips and a screwdriver or hex driver. These worm drive hose clamps can be easily removed and reinstalled, or made smaller or larger (cut off banding to make smaller; use a splice and additional banding to make larger).

Partial stainless steel hose clamps, which are recommended for most applications, have a stainless steel band; the plated screw and housing offer fair corrosion resistance. For good corrosion resistance, choose all stainless steel clamps, which have a stainless steel band, screw and housing. These quality hose clamps are made by a domestic manufacturer.

On single barb fittings, place the hose clamp in the recess. On multiple barb fittings, make sure the clamp is positioned over the barbs. Do not exceed the recommend tightening torque for the clamp.

These hose clamps are not suggested for use with soft hoses, such as silicone, because the hose can be extruded or sheared by the slots in the band. Also, make sure the clamp you select is suitable for the application.

Post time: May-25-2021

Whatsapp:+86 15222867341

Whatsapp:+86 15222867341