What is a Hose Clamp?

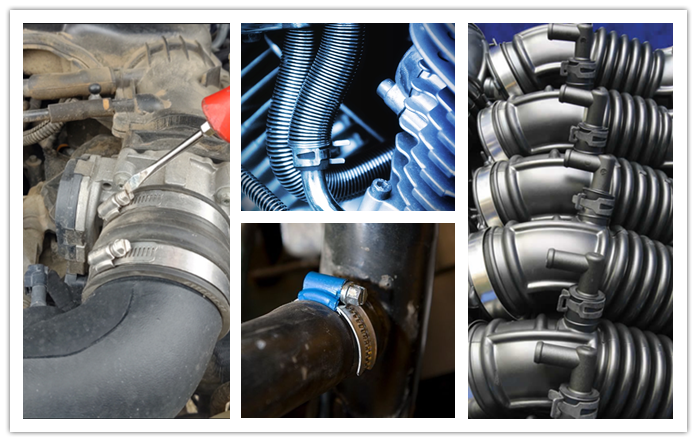

A hose clamp is designed to secure a hose over a fitting, by clamping the hose down, it prevents the fluid in the hose leaking at the connection. Popular attachments include anything from car engines to bathroom fittings. However, hose clamps can be used in a variety of different industries in order to secure the transportation of products, liquids, gases and chemicals.

There are four overarching categories of hose clamp; screw/band, spring, wire and ear. Each different hose clamp is used depending on the type of hose in question and the attachment at the end.

As one of the most regularly used hose accessories, questions surrounding the use of hose clamps are frequent and plentiful. The following guide will explain, the different types of hose clamps available, their uses, and how to care for your clamps. The different industries in which hose clamps are utilised will also be touched upon, answering all of your hose clamp questions in the process!

Please bear in mind that this article we will focus on screw/band clamps in particular, as they are one of the most common types of hose clamp. Therefore, the following information will be mainly concerning this clamp specifically.

How Do Hose Clamps Work?

1.A hose clamp is firstly attached to the edge of a hose.

2.This edge of the hose is then placed around a chosen object.

3.The clamp now needs to be tightened, securing the hose in place and ensuring that nothing from inside the hose can escape.

In general, screw/band hose clamps tend not to be used for ultra high-pressure scenarios, but instead are used frequently in lower-pressure environments, as well as when a quick fix is needed, especially within the home. That said, numerous industries utilise them, including the automotive, agriculture and marine industries.

What are the Different Types of Hose Clamps?

To fully understand how screw/band hose clamps work, we must look at the different types available. The most popular are the following;

1.Also referred to as worm drive hose clips, were the very first worm drive hose clip created, made in 1921. Extremely popular due to their simplicity, effectiveness and versatility,

2 Heavy Duty Hose Clamps; Heavy duty hose clamps, or Superclamps, do exactly what they say on the tin! Ideally suited to heavier-duty scenarios, heavy duty hose clamps are the strongest hose clamps on the market and are ideal for more difficult applications.

- 3 O Clips; The most economical form of hose clamp, O Clips work perfectly for the assembly of simple hoses, carrying air and fluid only. They are more flexible with their fitting than other hose clamps, as well as tamper-proof.

- All of the above come in a range of sizes, diameters and materials, to suit your specific hose needs.A hose clamp is firstly attached to the edge of a hose. This edge of the hose is then placed around a chosen object, and the clamp tightened, securing the hose into place, and ensuring that nothing from inside the hose can escape.

Post time: Jun-23-2021

Whatsapp:+86 15222867341

Whatsapp:+86 15222867341